Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

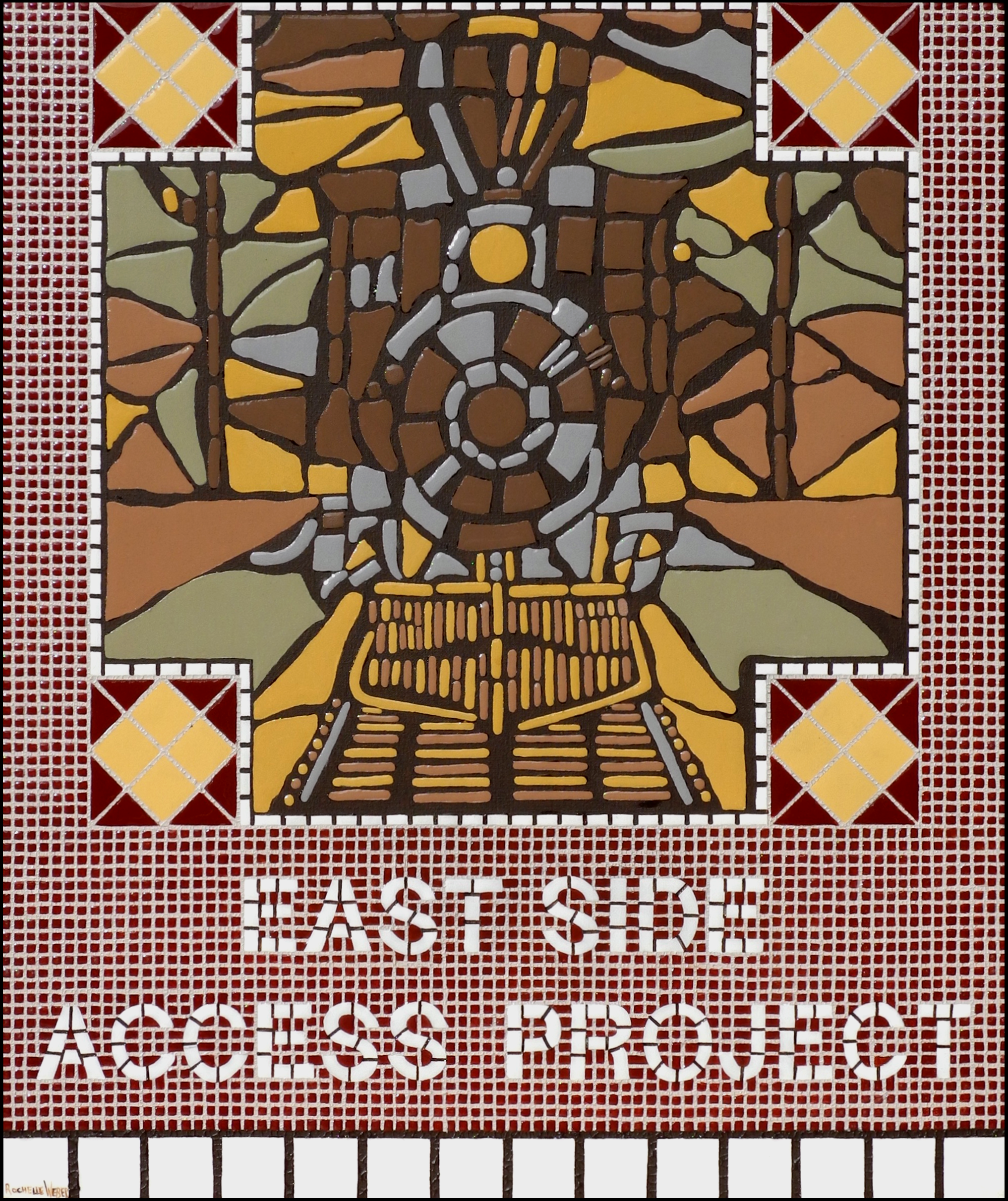

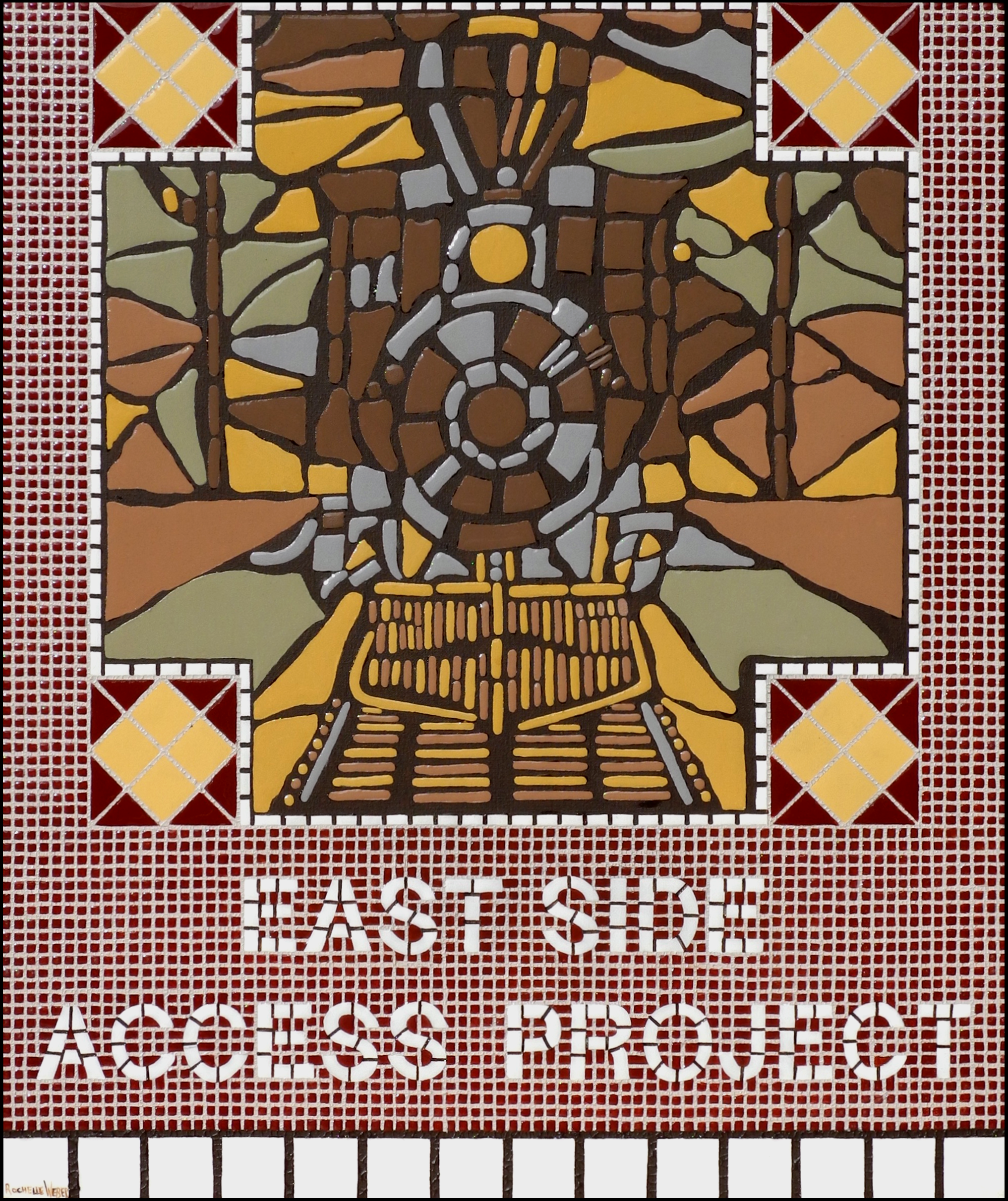

About Project

The East Side Access project, a massive infrastructure construction project in New York City that included the construction of a six-mile-long tunnel, underground subway stations, and a rail hub beneath Grand Central Station. AMBICO was responsible for designing and fabricating 275 pressure-resistant door and frame assemblies to keep commuters safe in case of emergencies. These doors protect specially designed rooms called “areas of refuge” between the tunnels.

Our Client’s Challenge

The challenging environment of the subway tunnels poses unique requirements for the pressure-resistant door and frame assemblies. They need to withstand the cyclical pressure load caused by passing subway cars and resist corrosion from saline water seeping through the walls. Additionally, the doors must meet rigorous fire performance standards. AMBICO had to be ready to fabricate the doors as construction progressed, which had been ongoing since 2007.

Our Approach And Solution

AMBICO was the ideal choice for this project due to our extensive expertise in specialized doors. We have a long-standing track record of successfully collaborating on transportation-tunnel projects and working closely with transportation professionals. Our team of engineers skillfully designed the pressure-resistant door and frame assemblies, incorporating structural stainless-steel sub-cores and fully welded door faces. Rigorous field tests were conducted, and we partnered with specialized lock manufacturers to ensure top-notch quality. The entire assembly, including hardware, doors, frames, glazing, locks, and hinges, received certification from an independent fire laboratory, guaranteeing its reliability. AMBICO’s international experience and adherence to Buy America regulations facilitated seamless coordination with suppliers and compliance with regulations. Our commitment to high-level coordination and service, including travel and inspection visits, has played a pivotal role in the project’s successful execution.