Decoding Brass Vs. Bronze: Unveiling Distinctions and ApplicationsBrass and Bronze Clad Doors and Frames are becoming increasingly popular in interior design and architectural circles due to their elegant and timeless appearance. While both brass and bronze are metal alloys and have warm, welcoming hues, they differ in color and composition. Bronze boasts richer, reddish tones in comparison to brass, creating a classic and inviting ambiance. Brass, on the other hand, has more yellow and gold shades in it. In this blog, we will explore the differences between brass and bronze, their unique characteristics, and why they are popular choices for decorative doors and doorframes. Additionally, we will take a closer look at brass and bronze clad doors and frames and their applications.

The question of whether brass holds an advantage over bronze is a common inquiry. However, it’s worth noting that both materials find their own niche applications. Brass and bronze are distinct metal alloys, each formed by combining two or more different metals. The composition of these alloys varies, defining their unique properties.

In the realm of modern bronze, a prevalent composition consists of 88% copper and 12% tin. Notably, bronze can also incorporate additional elements such as manganese, aluminum, nickel, phosphorus, silicon, arsenic, or zinc, contributing to its diverse characteristics. On the other hand, brass is primarily a fusion of copper and zinc, and the specific proportions of these constituents give rise to various types of brass. For instance, a common variant known as basic modern brass comprises 67% copper and 33% zinc. However, the proportions of copper and zinc can range widely, from 55% to 95% copper and 5% to 45% zinc, offering a broad spectrum of compositional possibilities.

Ultimately, the suitability of brass versus bronze depends on the specific context and requirements, as both alloys bring their own unique attributes to the table.

Brass production is believed to have originated around 500 BC, while bronze, tracing back to 3500 BC, boasts an even earlier history. In ancient times, brass was primarily employed in tool and weapon crafting, while bronze found its niche in jewelry and decorative arts. Over time, both metals diversified their roles, playing key parts in coinage, musical instruments, sculpture, and architectural endeavors. Today, brass and bronze remain integral materials, finding extensive use in both utilitarian and aesthetic contexts.

Both bronze and brass, with their appealing qualities, are often seen in many different interior design styles. Their warm and inviting colors make them excellent choices for adding a touch of elegance to homes and hotels. However, they do have noticeable differences, especially when it comes to color. Brass stands out for its shiny surface, lighter appearance, and subtle shades of yellow and gold. This makes it a popular option for bringing a sense of sophistication to spaces. On the other hand, bronze gives off deeper, reddish tones, creating a feeling of timeless tradition and a cozy atmosphere.

In recent times, bronze has gained significant popularity in the world of interior design. Its presence adds warmth and depth to rooms, making it a perfect match for livening up minimalist, neutral color schemes. Typically used as an extra touch, bronze can be found in various accessories like cookware, furniture, and lighting fixtures.

What is the Difference Between Brass and Bronze?

Exploring the differences between brass and bronze reveals unique characteristics that distinguish them. Besides their makeup, these metals have subtle variations that suit various uses. Bronze’s ability to resist saltwater corrosion makes it a prime pick for ship parts, while brass’s remarkable flexibility and ease of working make it perfect for crafting tubes and poles.

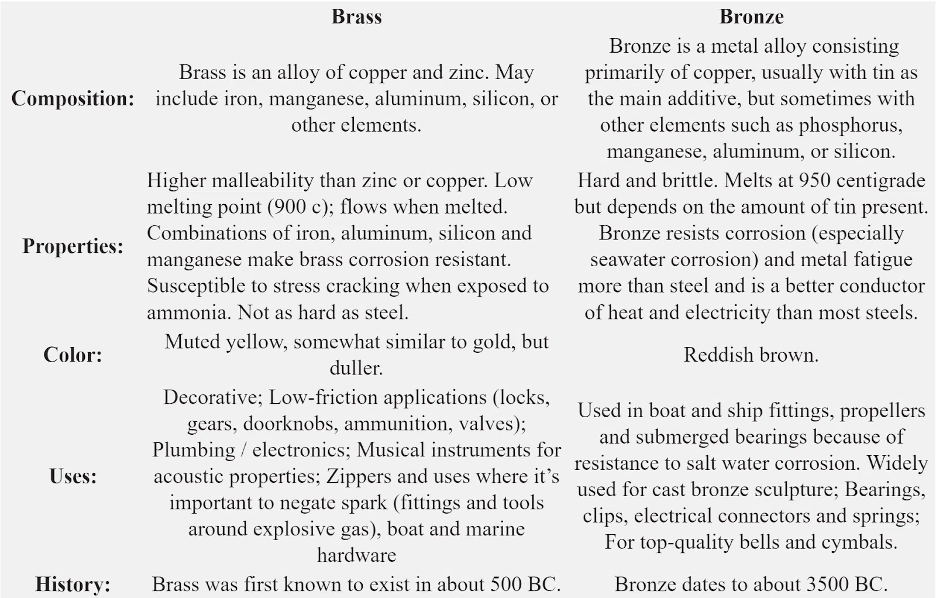

Take a look at Table 1 below to see some of the key distinctions between these two materials:

Table1

Is Brass Stronger Than Bronze?

When we look at the types of metal used, bronze is generally tougher than pure copper. On the other hand, brass is mostly made up of copper and zinc, which makes it stronger and more flexible. What’s interesting is that some mixtures of brass can be even harder than the individual metals they’re made of. This toughness actually comes from the softer metal in the mix, which is zinc. For example, an alloy with 50% zinc and 49% copper can be as tough as cast iron at -604, while an alloy with 66% copper and 33% zinc has a hardness of 472.

The steel sub frame (i.e., jambs, head and mullions when required) is formed as full frame profiles, and these are clad with brass and bronze in two or three parts to completely cover the base steel frame. The corners are made with the head butting between the two jambs, creating a beautiful vertical butt seam connection. With meticulous attention to detail, the door facing is skillfully secured to a resilient steel core. Doors can be manufactured in either a stile and rail configuration (when full or double lite glass is required) or full-face clad construction (with flush door(s) or those with narrow or half-vision lites).

The gleaming appearance of polished brass or bronze clad products projects a luxurious appearance at a surprisingly moderate cost. The antique finish of satin brass or bronze clad products suits the design requirements of historical renovation projects. Due to the the relatively light weight of this type of construction material, traditional builders’ hardware can be used. In addition, it offers the same ease of operation as traditional steel exterior door openings, including where accessibility is required.

What Types of Applications are Suitable for Brass Clad Doors and Doorframes?

Any opening that requires an elegant appearance can be supplied with a brass or bronze clad door or doorframe. The use of bronze material has been historically more common than brass. It was especially popular in the neo-classical and art-deco era of the early 20th century. Common applications include entrances to lobby areas in hotels and casinos, and lobby or common areas in posh corporate headquarters or prominent government buildings.

Are Brass or Bronze Clad Units Fire Rated?

Yes, both brass and bronze clad units have a fire rating. Fire rated doors are essential as they can help contain a fire from spreading to other parts of the building, reducing the chances of injury or loss of life. Fire rated doors can also help prevent structural damage to the building, saving time, money, and disruption. For more information on AMBICO’s fire rated brass and bronze clad door and frame assemblies, plese contact us.

AMBICO’s Completed Projects

Although our reputation may be tied to our engineered products, it is important to note that our decorative products have also gained global recognition for their use in historical buildings and restorations. In addition to offering enduring performance, our brass and bronze assemblies offer outstanding corrosion protection combined with exceptional design and beauty. In addition, we offer recessed panel steel doors that offer an old-world aesthetic with modern materials.

In 2017, AMBICO Limited was approached to lend its expertise to an ambitious plan to replace the original solid bronze doors at The Cadillac Place, in central Detroit. After close to a century of use, the doors had become worn and needed replacement. The goal was to install modern door and frame assemblies that met building codes while still honoring the building’s aesthetic heritage.

AMBICO’s designers incorporated aesthetic details that included stunning mitered corners and worked closely with the architects on the project to address heritage concerns while ensuring that the bronze cladding on the new doors was as close a match as possible to the original bronze doors. Today, the new bronze doors and frame assemblies at the Cadillac Place are in modern spirit, but with an old-world finish that harkens back to the 1920s.

Similar to the Cadillac place, AMBICO has successfully completed several signature projects such as Phoenix LDS Temple and Lafayette Building in Phoenix, Arizona, United States. The West Block in Ottawa, and Winnipeg’s Victory Building among several others.

Learn more about our projects on brass and bronze clad doors and assemblies at: